Engine Installations

From under-hood packaging and mounts to cooling airflow and aftertreatment, we design engine installations that hold up in test and in the field.

End-to-End Engine Packaging & Integration

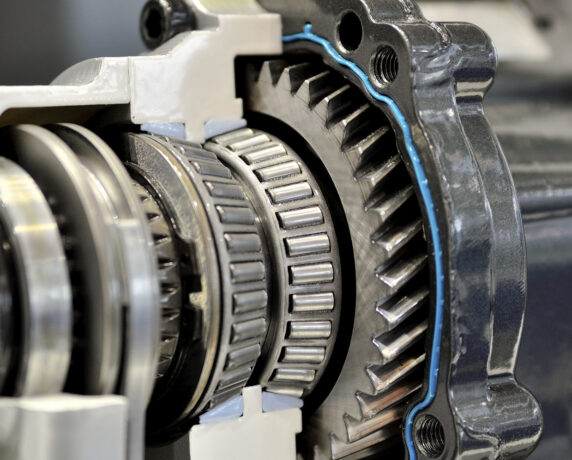

- Under-hood layout & packaging (ICE & hybrid): clearances, service envelopes, heat zones, shielding

- Cooling system architecture: radiator/CAC/condenser sizing, fans, shrouds, ducts, airflow paths

- Emissions/aftertreatment packaging: DOC/DPF/SCR, DEF tank & lines, sensor placement, thermal protection

- Mounts & isolation: engine/trans mounts, bracket design, torsional & NVH targets

- Intake & exhaust routing: backpressure targets, flex sections, hanger strategy, wrap & shields

- Fuel, fluids & hardlines: hose/hardline routing, retention, abrasion & heat protection

- Electrical integration: harness keep-outs, grounding, high-temp routing corridors

- Environmental & duty-cycle: sealing (IP), wading/splash, mud/salt, debris screens

- Serviceability: fasteners access, removal sequences, common maintenance tasks

- Quality & documentation: DFMEA, DVP&R mapping, drawing packs, change control.

- Deliverables: packaging CAD & sections, airflow/thermal rationale, mount/bracket drawings, aftertreatment layout, hose/line tables, shielding spec, DFMEA, DVP&R, and a validation test plan.

Built for Your Platform and Duty Cycle

Automotive & EV · Vocational trucks · Off-Highway/Ag · Industrial equipment · Specialty/Defense

We apply different clearance, thermal, and service targets for on-road vs. off-road and high-debris environments/

A Process that Holds Up in Prototype and Production

- Discover — install constraints, heat zones, maintenance tasks, and regulatory packaging needs

- Model & Plan — packaging study, cooling stack concept, airflow pathing, mount isolation targets

- Design — brackets, shields, shrouds/ducts, hose/line routing, fastener & access strategy

- Prototype & Bring-Up — build reviews, install trials, fit/finish & service checks

- Validate — cooling performance, thermal soak, NVH/idle shake, emissions system readiness (packaging support)

- Release — drawing pack, BOMs, DFMEA/DVP&R, supplier handoff

Toolchain: 3D CAD for DMU & interference checks; CFD for airflow pathing; FEA for brackets/mounts; structured DFMEA/DVP&R.

Emissions, Thermal, and Serviceability Done Right

- Aftertreatment packaging with appropriate heat shielding, sensor access, and DEF line protection

- Airflow management: sealing planes, shroud design, debris screens, fan selection

- Hot-surface protection and routing keep-outs for wiring/hoses

Service loops, common-tool fasteners, and removal sequences are documented for field service

FAQs

Do you work with specific engine brands?

Yes—we integrate with OEM packaging manuals and requirements for common engine families.

Can you design mounts and brackets?

Yes—bracket geometry, isolation targets, and fastener strategy with FEA as needed.

Do you handle emissions compliance?

We handle the packaging of aftertreatment and sensors and coordinate with calibration/compliance teams.

Can you support cooling test plans?

Yes—cooling performance & thermal soak plans with acceptance criteria; we’ll align with your test lab or internal rig.

How do you ensure serviceability?

We simulate maintenance tasks early and document tool access and part removal sequences.

Next Steps

Share your envelope constraints, heat zones, aftertreatment hardware, and timelines, and get a scoped installation plan by talking to an engineer. If you want your team to execute packaging studies, airflow/cooling reviews, and mount isolation with confidence, accelerate adoption by scheduling a training. Prefer examples, checklists, and acceptance criteria you can cite in reviews? Explore our technical publications.